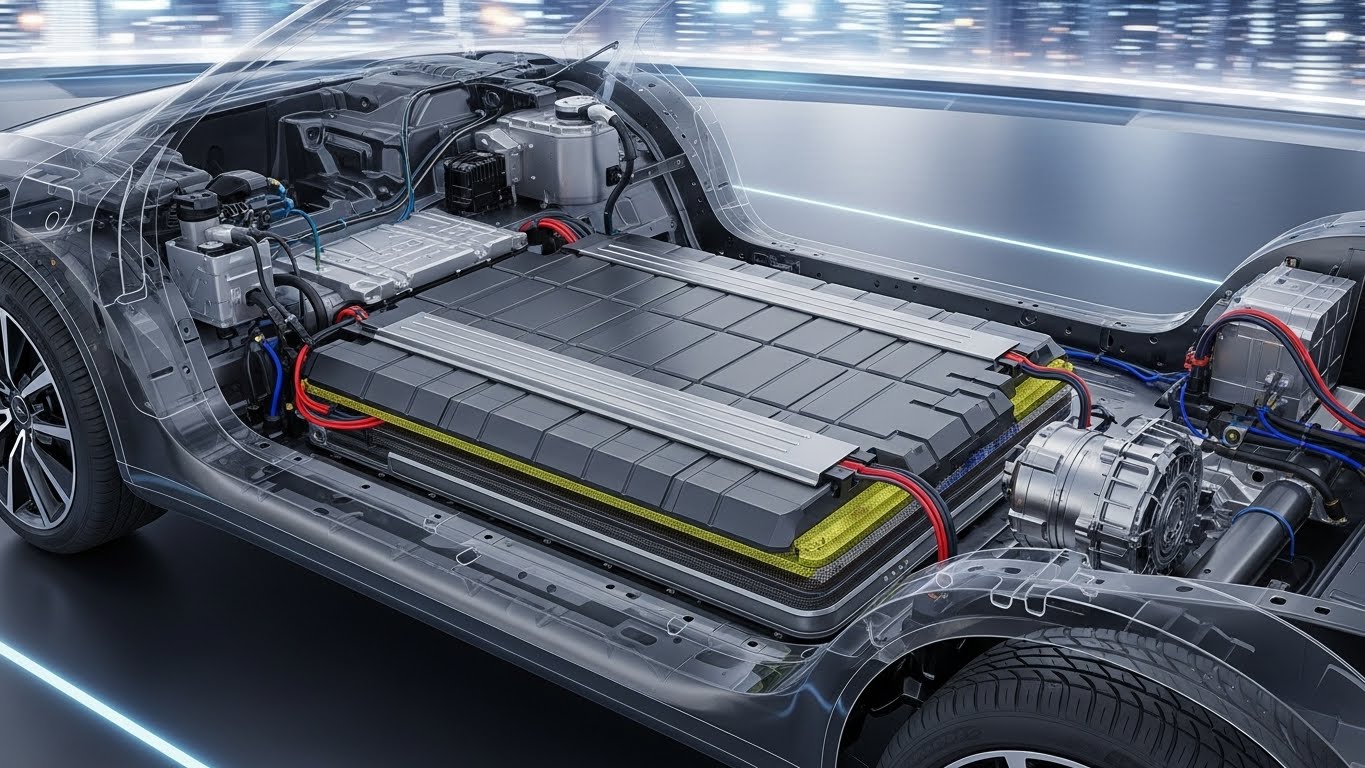

Electric cars have surged in popularity, but many drivers still worry about range anxiety – the fear of running out of charge. Part of the problem lies in the limitations of today’s lithium-ion batteries. Conventional packs typically deliver around 150–250 watt-hours per kilogram (Wh/kg), which constrains range (a 100 kWh pack might give ~300–400 miles). They also rely on liquid electrolytes that can heat up and even catch fire under stress. Rapid charging is hard too: high currents can plate metal on the anodes, reducing life. In fact, a recent study found over 80% of consumers hesitate to buy an EV because they worry about running out of range. In short, current batteries are heavy, energy-limited, and require slow, careful charging.

New solid-state battery (SSB) designs aim to change this. By replacing the liquid electrolyte with a solid material (often ceramic or polymer), SSBs promise much higher energy density and faster charging. For example, QuantumScape’s latest QSE-5 cell (designed for cars) has achieved about 301 Wh/kg – well above most today’s cells. Toyota notes this lets ions move faster, enabling “shorter charging times, increased cruising ranges, and higher power output”. In practice that could mean adding hundreds of miles of range in minutes, not hours. Solid electrolytes are also non-flammable, so the battery is far less prone to fire or thermal runaway – a major safety advantage over liquid-based cells. In short, SSBs could be smaller and lighter for the same capacity, or pack in much more energy for a given size.

Advances and Breakthroughs

A flurry of recent research and development shows solid-state batteries closing in on real-world use. Toyota, long a leader in batteries, is building on years of R&D: in mid-2023 it teamed with Idemitsu Kosan to develop sulfide-based solid electrolytes, aiming for mass production by 2027. Toyota still projects its first solid-state EVs around 2027–28, with “ultra-fast” 10-minute 10–80% charging and longer range. In one report Toyota engineers even suggested a 2025 prototype could reach 620 miles (1,000 km) – double today’s best EVs – using new lithium-based cathodes. In October 2023 Toyota warned, however, that durability is the “biggest challenge”: repeated cycling can crack the interfaces between cathode, anode and solid electrolyte, degrading the battery. So Toyota is aggressively tackling that issue in parallel with scaling up production.

Meanwhile, QuantumScape (backed by Volkswagen) is making headlines. Its first product, the QSE-5 solid-state cell, is a ~5 Ah pouch cell for auto use. In October 2024 QuantumScape began delivering test samples of QSE-5 to carmakers, boasting 844 Wh per liter (≈301 Wh/kg) energy density. The company says QSE-5 can recharge from 10% to 80% in about 12–15 minutes (at moderate pressure) and even operate down to –30 °C. In mid-2025 QuantumScape announced an expanded deal with VW’s PowerCo to build a pilot production line for QSE-5 cells. This “Eagle Line” is due in early 2026 and is meant to demonstrate SSB manufacturing at scale. In fact, VW is already using prototype QuantumScape cells in a Ducati electric motorcycle test program. The take-away is that solid-state cells are moving from lab to pilot plant with VW’s direct involvement.

Solid Power, another leading SSB developer (with Ford and BMW as partners), also reports progress. It has shipped dozens of production-line 5Ah cells (with a sulfide electrolyte) to Ford and BMW for testing. In May 2025 BMW announced it is running a test i7 sedan with Solid Power’s pure solid-state cells. BMW says the demonstrator already shows the promise of “higher energy density in a very compact storage system” compared to today’s batteries. BMW and Solid Power aim to begin pilot lines in Germany by 2025 (for testing), with full-scale SSB production closer to 2030. Ford, which owns part of Solid Power, is also building 100 Ah full-scale SSB cells for vehicle tests. And in 2024 Solid Power partnered with Korean battery-maker SK On to install a pilot SSB line in Korea by 2025. The goal is to prove Solid Power’s electrolyte and designs can scale up – a key step toward lower costs and commercial kits.

Other automakers and labs are moving fast too. Hyundai has gone all-in: in early 2025 it opened an SSB “Dream” battery pilot production line (part of a $9 billion R&D push) and expects to show prototype EVs with these cells by late 2025. In February 2025 Hyundai publicly demonstrated its new solid-state EV battery line and said SSBs (nicknamed “Dream batteries”) could unlock more range, faster charging and significantly higher energy density, though they caution “stability and manufacturing hurdles” remain. Nissan also plans SSB EVs by the end of this decade (with a new Yokohama pilot plant opened for SSB development). Even Stellantis (Peugeot, Chrysler etc.) is testing semi-solid batteries: it plans a 2026 demo fleet (Dodge Charger Daytona EV) using a polymer-based SSB from Factorial Energy. In short, virtually every major carmaker has SSB prototypes in the works.

Vehicles and Commercial Outlook

Real-world testing of solid-state packs has already begun. Aside from BMW’s i7 test car, Daimler and Mercedes have reportedly run prototype SSBs in vans in 2024, and VW is said to be evaluating QS cells in a Ducati e-motorcycle. Ford and GM (through its joint venture with Hyundai) have talked about building test cars once reliable SSB cells are ready. Nissan explicitly targets SSB EVs by 2028, suggesting a next-generation Leaf or Ariya might use them. Hyundai is eyeing its new “eM” platform cars (like an Ioniq 9 three-row) for SSB power by the early 2030s. In China, startups are even exploring SSB variants of existing models (for example, SAIC’s MG4 hatchback has a semi-solid pack in tests). Overall, most companies expect the first SSB-powered road cars around 2027–2030. Beyond that, if SSBs deliver on promise, EV ranges could jump 30–50% for the same pack size.

Early performance data is still limited, but the trends are positive. Solid-state packs run cooler and claim to tolerate much higher charge rates. Industry analysts say modern SSB designs could do 10–80% charging in as little as 15–20 minutes, far faster than typical Li-ion EVs. They also degrade more slowly: a WardsAuto analysis notes that solid-state cells might last “double or triple” the lifespan of today’s batteries. Safety is clearly better: the Toyota press release highlights that solid electrolytes are inherently more stable under heat and high voltage, and Hyundai’s tests show puncture/freeze resilience superior to liquid packs. In sum, the real-world tests so far confirm the expected gains: longer drives, quicker top-ups, and fewer risk of fires.

Remaining Challenges

Despite the hype, solid-state batteries still face significant hurdles before they can replace today’s packs. One is dendrite growth and voids. Lithium metal anodes (used for top energy) tend to form filaments (“dendrites”) that can short-circuit a cell. Repeated cycling can also cause tiny gaps or cracks at the interfaces. Toyota explicitly warns that SSB durability is challenging: “cracks between the cathodes and anodes and the solid electrolytes” from cycling degrade performance. Researchers at the University of Houston recently shed light on this: they used electron microscopy to film how microscopic voids merge and cause failure in real-time. By tweaking the chemistry (adding a bit of magnesium to the lithium), they could heal those voids and allow the cell to run under much lower pressure, greatly improving stability. These insights are promising, but it shows how finely tuned the materials must be.

On the manufacturing side, solid electrolytes pose new problems. A WardsAuto report notes the thin solid films are “fragile”, and assembling them at large scale without huge scrap is “production hell”. Automakers talk about yields in the low single digits. Cost is another gap: today’s lithium-ion packs cost ~$112/kWh at the pack level; the first SSB prototypes are around $400–$500/kWh. Even startup Factorial admits its polymer semi-solid cells are 10–30× the cost of Li-ion. Scaling up to gigawatt volumes will require new high-speed deposition machines for ceramics or sulfides and giant raw material plants (Idemitsu is already building a lithium sulfide factory). The resulting cars would be expensive initially; analysts expect SSBs only to approach cost parity with Li-ion after 2030.

In summary, the path to solid-state EVs is steep. Engineers must conquer materials science and mass production simultaneously. But the payoff could be huge: in principle, SSBs “can store more energy than traditional lithium-ion batteries”, extending range 30–50% for no extra weight. They also allow far faster charging with less cooling, and dramatically lower fire risk. Many car companies and labs are racing toward that goal. Even if the first SSB-powered cars arrive only in the late 2020s, they could usher in multi-hour-range EVs and make battery overheating concerns a thing of the past.

The electric revolution still needs breakthroughs like solid-state batteries to fully mature. But with Toyota, Volkswagen (QuantumScape), Hyundai, BMW, and others pushing hard, the age of 1,000-mile EVs and 10‑minute fast-charging is looking closer than ever.

Sources

Solid-State Batteries Progressing for Longer-Range EVs, But Is Outlook Too Rosy? | WardsAuto

https://www.wardsauto.com/news/solid-state-batteries-progressing-for-longer-range-evs-but-is-outlook-too-rosy-/799126/

A First Look at the QSE-5 B Sample – QuantumScape

https://www.quantumscape.com/blog/a-first-look-at-the-qse-5-b-sample/

Idemitsu and Toyota Announce Beginning of Cooperation toward Mass Production of All-Solid-State Batteries for BEVs | Corporate | Global Newsroom | Toyota Motor Corporation Official Global Website

https://global.toyota/en/newsroom/corporate/39865919.html

University of Houston Scientists Recharge Battery Potential | University of Houston

https://www.uh.edu/news-events/stories/2025/june/06052025-battery-life.php

Ford Boosts Investment in Solid Power, Aiming to Accelerate Solid-State Vehicle Battery Development for Customers | Italy | Italian | Ford Media Center

https://media.ford.com/content/fordmedia/feu/it/it/news/2021/05/03/ford-boosts-investment-in-solid-power–aiming-to-accelerate-soli.html

Toyota Lays Out Its EV Battery Road Map, Including a Solid-State Battery (Eventually)

https://www.caranddriver.com/news/a45942785/toyota-future-ev-battery-plans/

Solid-state batteries: QuantumScape ready to launch its pilot line – electrive.com

https://www.electrive.com/2025/12/10/solid-state-batteries-quantumscape-ready-to-launch-its-pilot-line/

BMW Group and Solid Power are testing all-solid-state battery cells in a BMW i7.

https://www.press.bmwgroup.com/usa/article/detail/T0450262EN_US/bmw-group-and-solid-power-are-testing-all-solid-state-battery-cells-in-a-bmw-i7?language=en_US

Solid Power Inc. – Solid Power and SK On Deepen Partnership with New Agreements

https://solidpowerbattery.com/investor-relations/investor-news/news-details/2024/Solid-Power-and-SK-On-Deepen-Partnership-with-New-Agreements/default.aspx